Gear Box - Technical Details

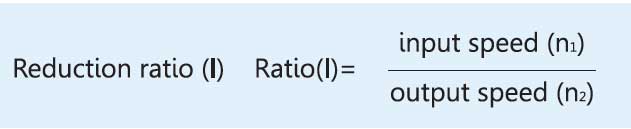

Generated Torque / Gear Motor Delivered Torque T1 (Nm)

This is net Torque delivered to output shaft while prime mover of capacity P (Kw/Hp) coupled gear drive.

- O> Efficiency is taken into consideration.

- O> Calculation confirms to 10,000 hrs of service life.

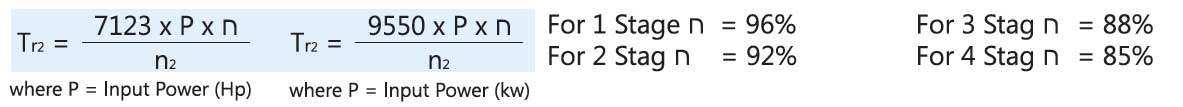

Rated Torque / Output Torque T2(Nm)

This is the torque output which gearbox can transmit safely.

- O> 10,000 hrs of service life.

- O> values are derived from ISO DP6336.

Required Torque Tr2 (Nm)

It is a torque demanded/required by the end use application to get the work done.

It should always be less than T2 by service factor value S.

It should always be less than T2 by service factor value S.

Selection Torque Ts2 (Nm)

It is a final torque value calculated for selection of gear box taking into consideration application required service factor S.

Ts2 = Tr2 x S < T2

Ts2 = Tr2 x S < T2

Input Power P1 (Kw / HP)

It represents the input prime mover's power avialable for the gear drive.

It is the combination of the output speed (n2) and the relevant output torque (T2).

It is the combination of the output speed (n2) and the relevant output torque (T2).

Output Power P2 (Kw / Hp)

It is net power avialable at output shaft considering efficiencies of each stage of gear drive.

Life Index / Load Cycle n2.h

It is the product of output speed of the gear drive and expected life of the gear drive in hours.

e.g. : Output speed n2 = 40 rpm, Life required h = 12,500 hours

n2.h = 40 x 12,500 = 5,00,000

e.g. : Output speed n2 = 40 rpm, Life required h = 12,500 hours

n2.h = 40 x 12,500 = 5,00,000

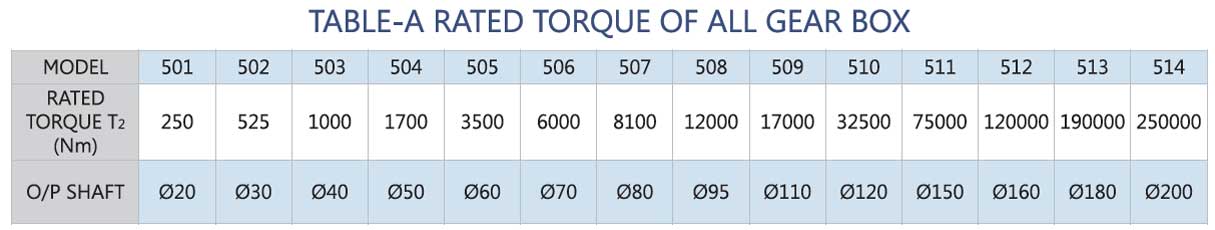

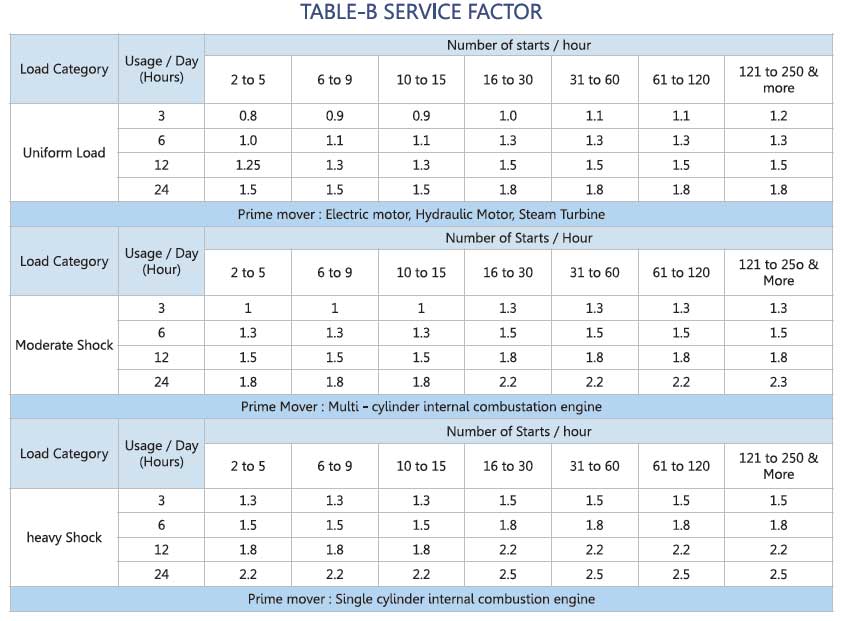

Service Factor Sf

It is a number which is derived by taken into consideration.

- O> Number of start and stops per hour

- O> Type of load ( uniform, Moderate, Heavy )

- O> Number of hours of work per day.

Itgives general guideline to design engineer to slect gear drive properly according to severity of application. Refer Table no : B for operation specific service factor selection table which covers industry specific application to prevent designer from selecting under rated gear drive. It also act cross checking for analayzing previsouly calculated service factor.

Thermal Rating Pt (Kw)

Thermal rating is limiting value of maximum mechanical power that can be tansmitted by the gear drive without overheating (i.e. sump temerature not getting above 90-95℃ & overall casing temprature not getting above 80-85℃), Which is necessary for the satisfactory working of gear drive for stipulated time frame. Values are derived based on the following conditions.

- O> Lubrication system splash

- O> Mounting Horizontal

- O> Input speed 1140 rpm

- O> Ambient temp. 30℃

- O> Use Continuous

- O> Max. oil temp. 90℃

- O> oil grade VG 220

Thermal rating value should not be taken into consideration in case of continuous duty for max. 1.5 hours followed by sufficient enough gap ( 1.5 - 2 Hours ) to bring gear back to an ambient temperature.

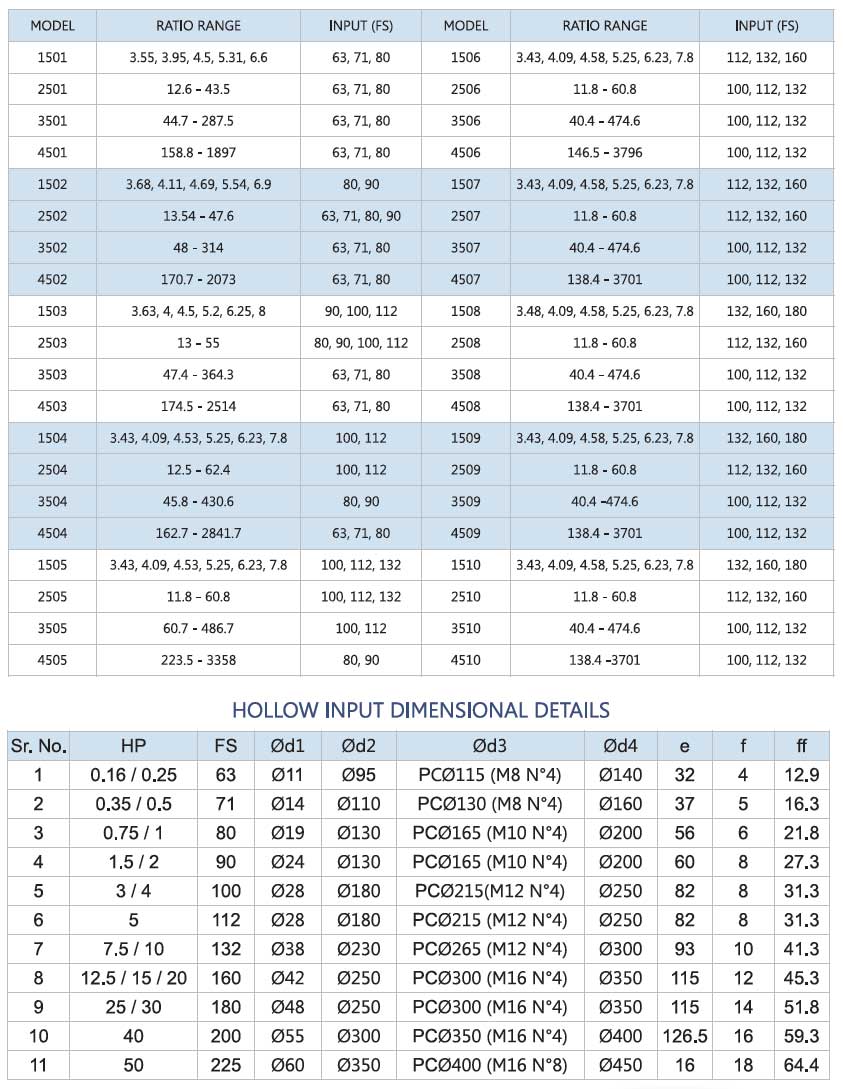

Range of Rations and frame size suitable for diffrent models

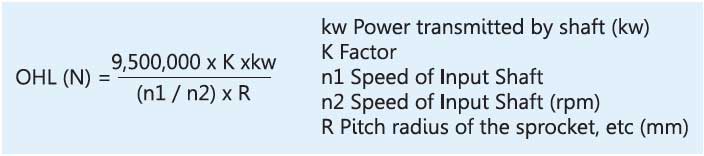

Radial & Axial Load Fr & Fa

Radia Load Fr

Permissible radial and axial load carrying capacity of the gear drive isbased on the nominal bearing life chosen.When a sprocket , gear or pully is mounted on the input or output side of the shaft, radial load (overhung load) will act on the shaft and consequently on the bearings.

For satisfactory operation of the reducer calculated overhung load on the shaft should not exceed the tabulated value for any specific gear drive.

Permissible radial and axial load carrying capacity of the gear drive isbased on the nominal bearing life chosen.When a sprocket , gear or pully is mounted on the input or output side of the shaft, radial load (overhung load) will act on the shaft and consequently on the bearings.

For satisfactory operation of the reducer calculated overhung load on the shaft should not exceed the tabulated value for any specific gear drive.

Axial Load / Thrust Load Fa

No check or calculation is required if the axial load towards or away from the unit is 50% of the permissible overhung load. If the axial load on the unit exceeds considerably or there is combination of axial and radial load plese contact us.

Lubrication

For the best performance of the enclosed industrial gear drives proper selection of the lubricating agent is indispensable. Unless otherwise specified gear drive are supplied without oil fill. Lubricant serves following purpose:

- O> Reduces friction reduces/prevents wear. Carries away generated due to friction

- O> Protects against corrosion

There are three kinds of lubricants : Liquids ( mineral / vegetable oils ) Semi-solids ( grease ) Solids ( graphite, molybdenum disulfide )

Lubricant should satisfy following constraints of the gear drive at diffrent working conditions :

Lubricant should satisfy following constraints of the gear drive at diffrent working conditions :

- O> Speed - Lesse the output speed more viscous the lubricant required. Higher speed necessitates use of synthetic based oils.

- O> Temperature - Higher the output speed higher the temperature lesser the viscosity grade of the lubricant required.

- O> Pressure - High Pressure usually requires synthetic base EP additives.

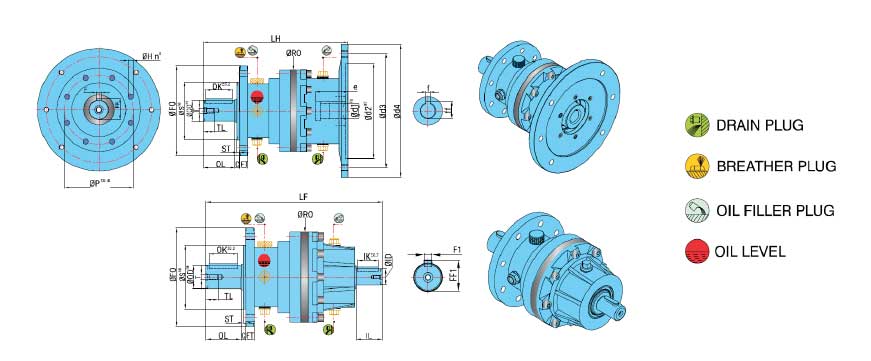

Dimensional details for flange mounted gear drive

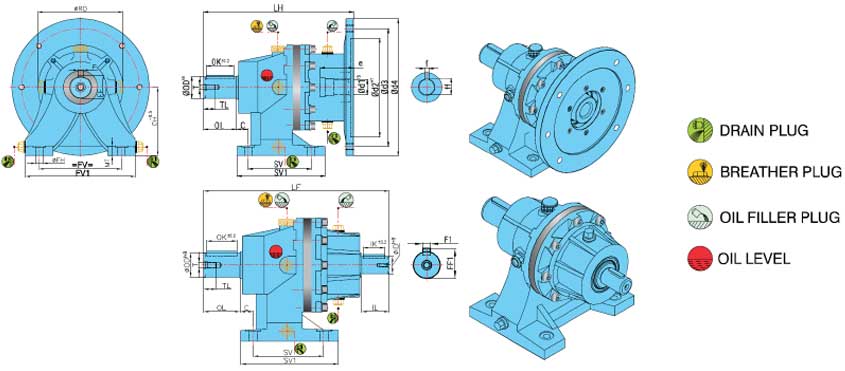

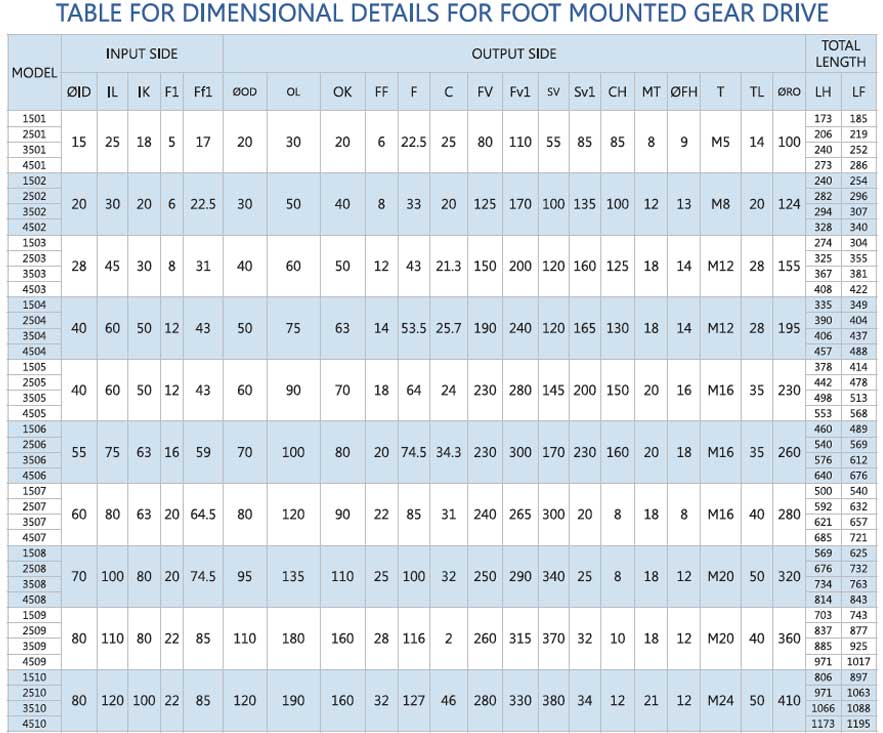

Dimensional details for foot mounted gear drive

Better Transmission, Greater Result ...

Planetary Gearbox

- O> Model : 501 - 515

- O> Ratio : 1:3.63 to 1:100000

- O> Rated Torque : 12 kg.m to 60,000 Kg.m

- O> Input Power: 0.12 Kw to 315 Kw

- O> Mounting : Foot / Flange / Agitator

- O> Input : Hollow to suite 63 Fs to 355 fs & male free shaft

Warm Planetary Gearbox

- O> Model : WP501 - WP4511

- O> Ratio : 1:26.6 to 1:100000

- O> Rated Torque : 12 kg.m to 8000 Kg.m

- O> Input Power: 0.12 Kw to 37 Kw

- O> Mounting : Foot / Flange

- O> Input : Hollow to suite 63 Fs to 355 fs & male free shaft

Bevel Planetary Gearbox

- O> Model : BP1501 - BP4515

- O> Ratio : 1:3.63 to 1:100000

- O> Rated Torque : 12 kg.m to 60,000 Kg.m

- O> Input Power: 0.12 Kw to 315 Kw

- O> Mounting : Foot / Flange

- O> Input : Hollow to suite 63 Fs to 355 fs & male free shaft

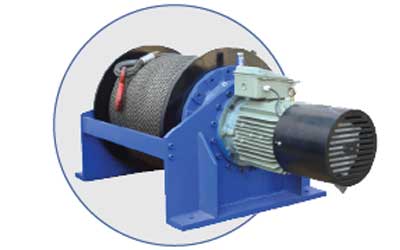

Electric Winch

- O> Model : SEW0.5 - SEW20

- O> Capacity : 500Kg to 20,000 Kg

- O> Speed : 3m / min - 25m / min

- O> Wire Rope : Φ6 to Φ38 & L10 m - 1000m

- O> Drum : Single / Double

Hydralic Winch

- O> Model : SWH0.5 - SWH20

- O> Capacity : 500Kg to 20,000 Kg

- O> Speed : 15m / min - 40m / min

- O> Pressure : 50 - 200 Bar , Flow - 25 - 100 Lpm

- O> Wire Rope : Φ6 to Φ38 & L10m - 100m

- O> Drum : Single / Double

- O> Supplied with negative parking break

Winch Drive

- O> Model : SWD1502 to SWD4512

- O> Ratio : 1:40 to 1:1000

- O> Rated Torque : 12Kg.m to 60,000 Kg.m

- O> Input Power : 0.12 Kw to 315 Kw

- O> Mounting : Body

- O> Input : Hollow to suite 63 Fs to 355 fs & male free shaft

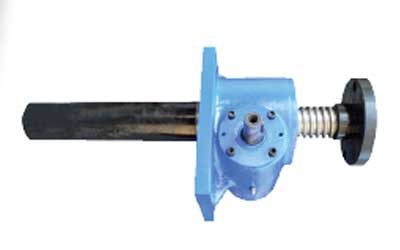

Screw Jack

- O> Model : SSJ25 - SSJ190

- O> Capacity : 0.5 Ton to 100 Ton

- O> Stroke : 30mm to 4000mm

- O> Roatating and Translating Screw Trapazoidal and ACME thread.

Track Drive

- O> Model : STD160 - STD415

- O> Ratio : 1:5.25 to 1:39.5

- O> Rated Torque : 100Kg.m to 4000 Kg.m

- O> Face seal for longer life

- O> Rigid Design

- O> Hydralic Releasing Parking Break on request.